Highlights &

advantages

traceability

ERP system

times

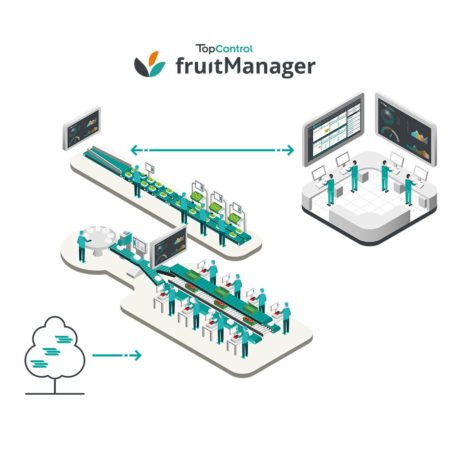

Storage Move

Our innovative software solution guarantees the recording of all logistical processes in interaction with the sensors installed on the forklift and enables a 3D visualisation of the warehouse in real time. The system provides an inventory maintenance with exact positioning of every transport unit, as well as an automated and mission-linked control of the forklifts. StorageMove contributes to an increase of productivity and an optimisation of resources. Thanks to the modular structure the system can be used in all kind of corporations. The number of forklifts used and the size of the storage area to be visualised are not limited. The type of forklifts used is just as irrelevant as the shape of the transport units moved.

Logistic-steering-system for warehouse-handling

Complete 2D or 3D visualization of the ware in real time

Resource optimisation of box logistics

Tailored to customer requirements

Optimisation of the order management

Support of the FIFO (First In First Out) principle

Fully automated productivity analysis and statistics

productivity increase

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

- Aapplicable indoor and on different area levels. It is even possible to use it inside of cold storage cells.

- Wearless and maintenance: the installed technology on the forklifts is free of mechanical abrasion

- Possibility of flexible and individual integration with the existing software

- Big structural and mechanical alteration of the storage structure is not necessary .

- Logistical advantages of a fully automated high are assured with a bay warehouse fractional amount of whose costs.

- Continuous improvements and further developments

Application areas and compatibility

Downloads

Perfect warehouse handling and detailed overview

Graphical visualisation

The system provides an inventory maintenance with exact positioning of every transport unit, as well as an automated and mission-linked control of the forklifts.

StorageMove contributes to an increase of productivity and an optimisation of resources.

Complete 2D or 3D visualization of the ware in real time

Resource optimisation

Resource optimisation of transport unit logistics. By monitoring the process, the system reports the need for more boxes at the exact time. The forklift is directed to the location of the required article precisely and reliably.

Easy and costefficient implementation

Only the equipment for the forklifts with sensor technology needed. Big structural and mechanical alteration of the storage structure is not necessary

Applicable indoor and on different area levels. It is even possible to use it inside of cold storage cells.

Wearless and maintenance-free (the installed technology on the forklifts is free of mechanical abrasion).

Logistical advantages of a fully automated high bay warehouse are assured with a fractional amount of whose costs.