INTELLIGENT

PACKAGING SOLUTION

INTELLIGENT

PACKAGING SOLUTION

IPS

INTELLIGENT

PACKAGING

SOLUTION

IPS

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard

THE BEST SOLUTION OPTIMIZED FOR food products that are subjected to quality control and weighing for packaging.

Contact us for more information

Highlights &

advantages

construction

productivity

of the giveaway

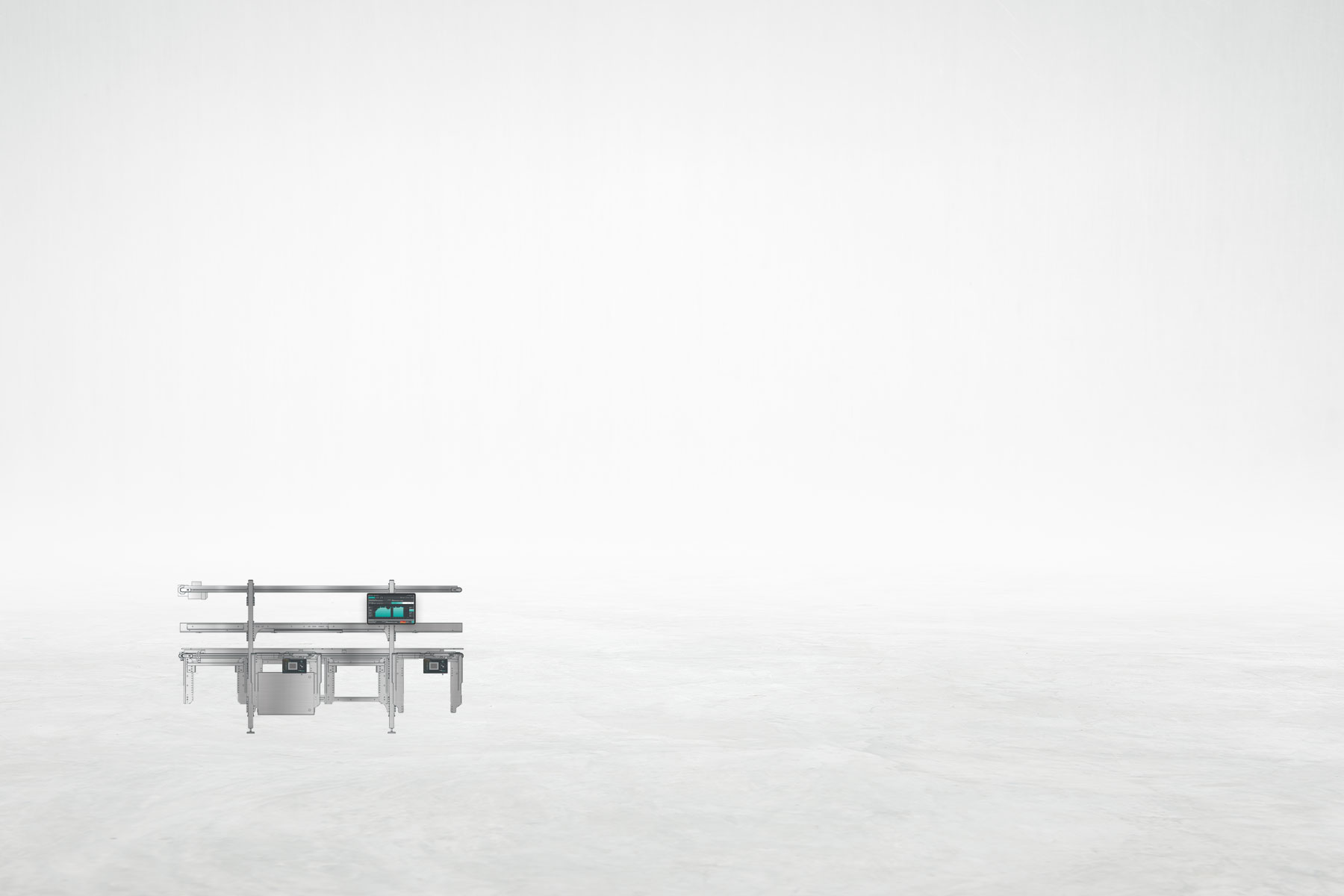

Packing line – IPS

The TopControl packaging lines are precise and cutting-edge customised lines for every requirement.

From planning till installation TopControl cares about everything. All from one single source – like that there are no component interfaces that might cause faults. The perfect match between individualised development and proved installation.

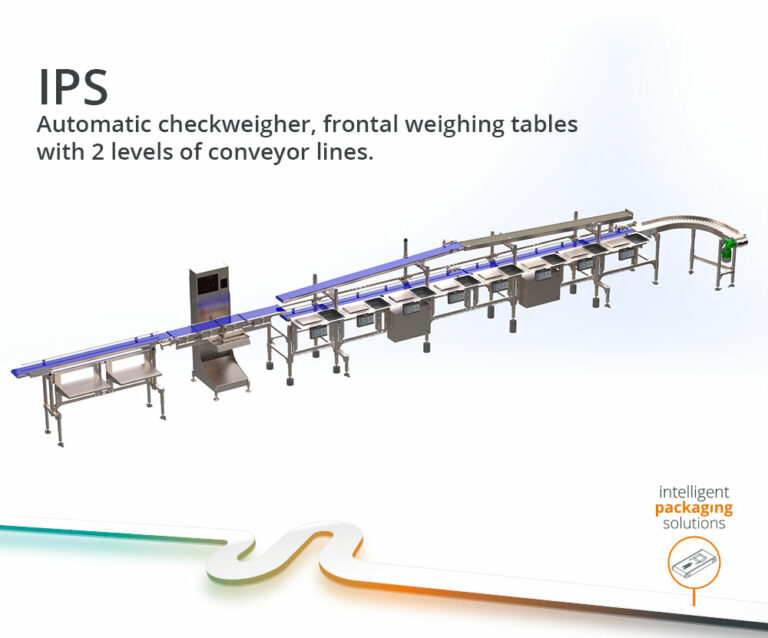

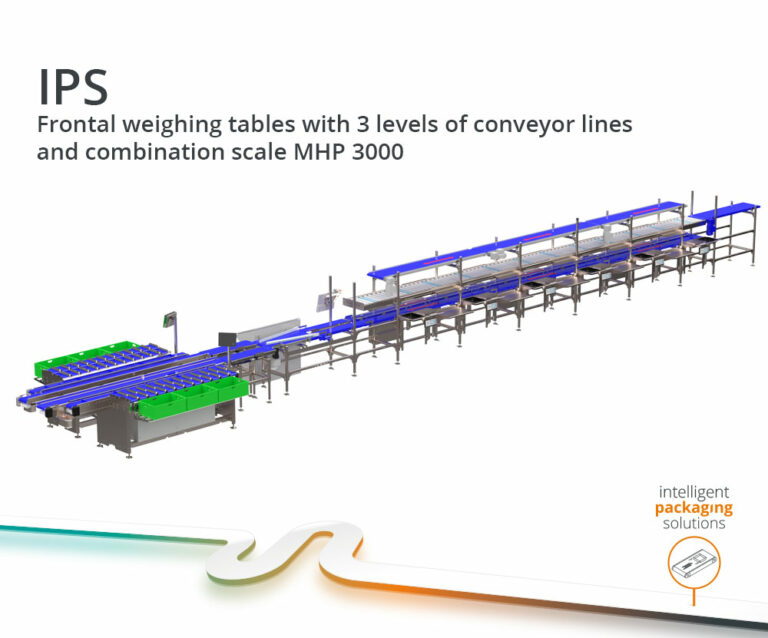

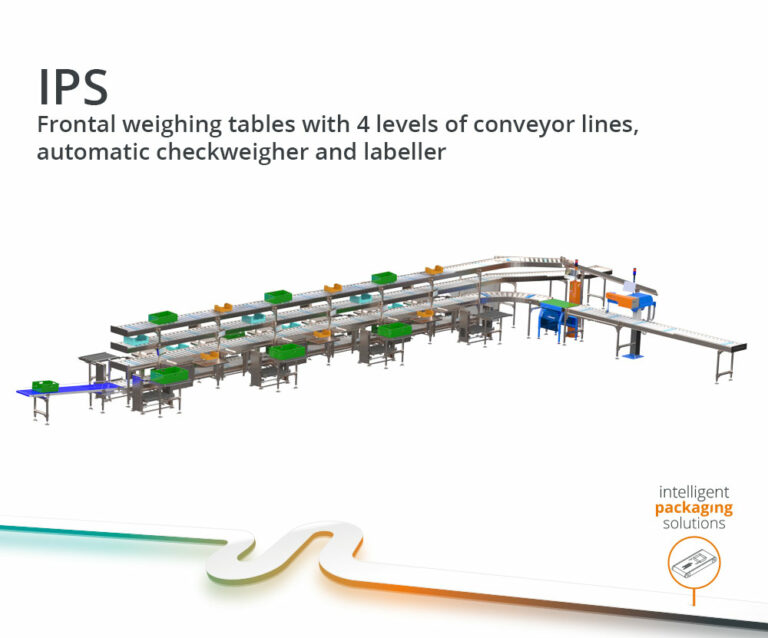

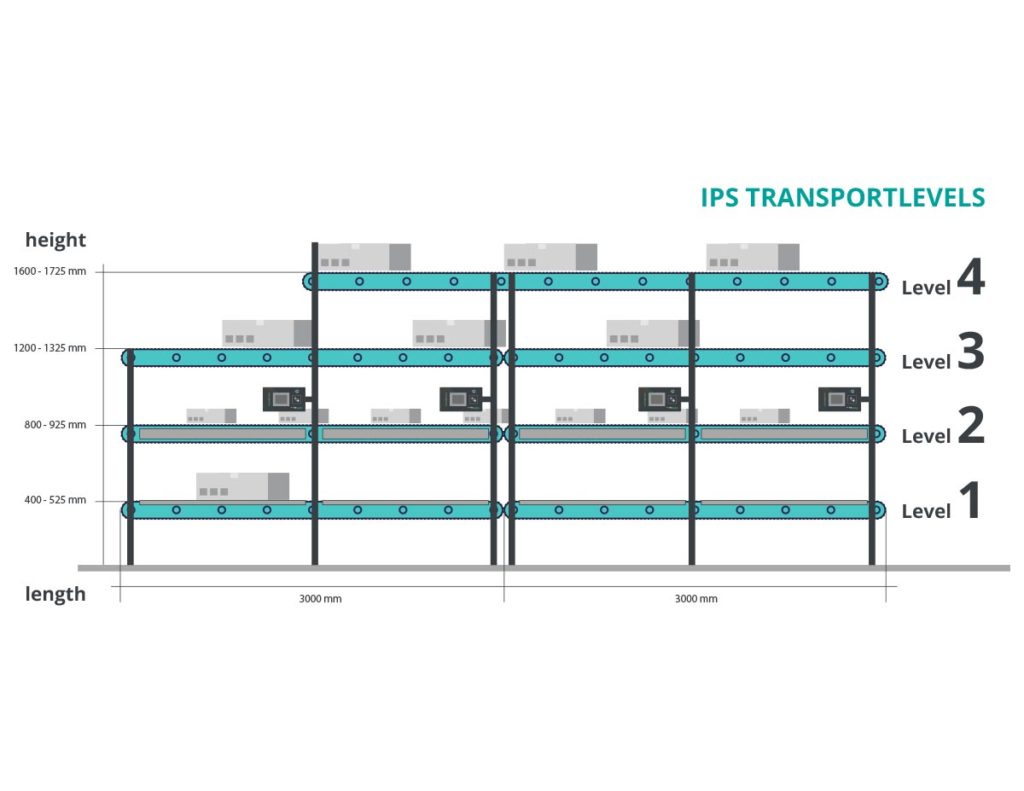

The packaging line is convincing due to its modular design. 1 to 4 possible transport levels can be selected. Level 2 is necessary in any case – it is the working level. One module of the packing line has a length of 3000 mm.

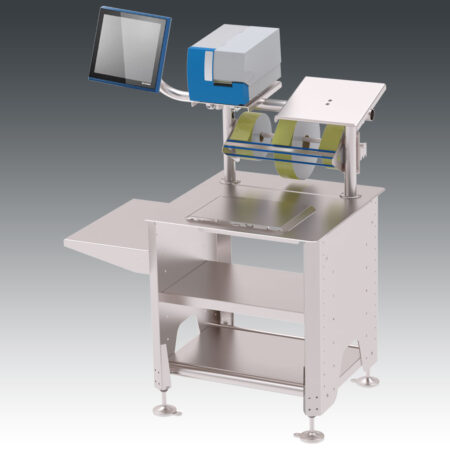

Large, smart weighing tables equipped with innovative lighting technology can be integrated into the packing line.

The line can be personalised with the following options:

- Conveyor belts with the right width for trays or crates

- Roller conveyors with the appropriate width for punnets or boxes, which can optionally also be motorised.

- Box turnouts

- Discharge slides

- Curves for punnets and boxes with 45°, 90° or 180°

- Frontal weighing tables with and without box storage, weighing platforms for punnets or boxes, integrated daylight illumination and waste bins.

- Side weighing tables in single or double design with or without box storage, weighing platforms for punnets or boxes, integrated daylight illumination in the Corona-compliant plexiglass partition and waste bins.

Ergonomic, robust & hygienic workplaces

Maximum packaging speed and productivity

Profit maximization

ROI 3-12 month

Flexible use

Maximum reduction of giveaway

Transport belt for automatic or manual transfer of the combined product to the following station

Minimisation of the work steps

Intuitive touch display

Efficient staff time recording with integrated RFID reader

Complete control and registration through the TopControl software

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

- Maximum reduction of the giveaway and maximum increase of the productivity

- Integrated LED indicator

- Profit maximization

- Individual adjustment of levelling or extraction weighing definable per article

- Packing according WELMEC 6.4/℮ for finished packs

- ROI within 3-12 months

- Complete control and registration of weight and performance data through the TopControl software

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

Downloads

Highlights of the IPS packaging line

Working levels

The packaging line impresses with its modular design. 1 to 4 possible transport levels can be selected. Level 2 is necessary in any case – it is the working level. One module of the packing line has a length of 3000 mm.

Integrated system scale

The levelling scale optimises the giveaway of the goods to be packed. Integrated in the network, the weights are recorded directly in the central TopControl software, thereby increasing yields by avoiding unnecessary overcrowding. The high accuracy of the scale and the intuitive operation allow considerable savings in time and product costs.

FUNCTIONS

- Dynamic control of weight limits, levelling or removal weighing definable per item

- Recording of incoming batches and waste

Sophisticated details

Conveyor belts: The conveyor belts can be used on all levels. Depending on whether the products are packed in punnets or boxes, the appropriate conveyor belt width will be chosen.

Roller conveyor: The roller conveyor is available with and without motor. They can be used at all levels. Depending on whether the products are packed in punnets or boxes, the appropriate roller conveyor width will be selected.

Tray ejector: The tray ejector can be combined with a conveyor belt width of 200 mm and can be used on level 2.

Box switch/turnout: The automatic box switch is used on level 1 and 2. This way, the boxes will be automatically ejected at the respective workstation without the workers having to manoeuvre them from the conveyor belts or roller conveyors to the workstation.

Frontal worktables: TopControl’s frontal, smart weighing tables are delivered mounted on the packing line. They are available with or without crate storage. Integrated into a customer-tailored packing line, they make the packing and repacking process easier than ever before.

Operation is child's play: whether stand-alone or integrated via foodProcess, the IWS 200 adapts flexibly to your processes.

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.