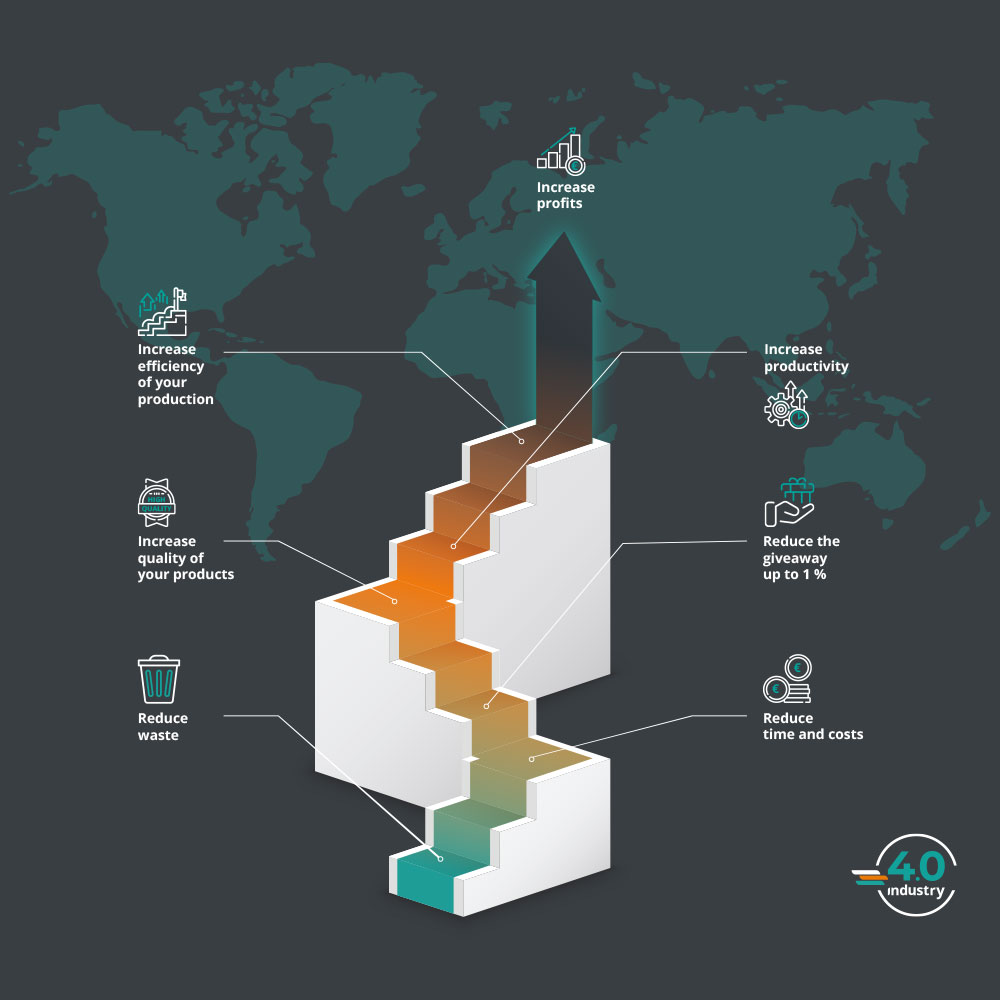

Highlights &

advantages

traceability

ERP system

times

FruitManager

FruitManager is a system solution especially developed for the fruit and vegetable sector that enables you to automatise production processes and logistics. The FruitManager directs and controls the entire processes. The supervisory data acquisition provides the necessary information for a complete documentation and traceability according

to the applicable eu regulations.

With the TopControl FruitManager solution, your company saves time and money. Our FruitManager is a proven improvement in companies of all sizes in the food industry. Facilitate and automate production and process control with 100% traceability. Through constant analyses of the system, you optimise productivity, process flows as well as your personnel resources.

TOTAL SOLUTION: The possibilities of the Fruitmanager are limitless, because it can be used in all possible expansion stages. for instance as a com-plete system that processes the entire production from the goods receipt to the goods issue.

INDIVIDUAL SOLUTIONS: The diverse forms of application support existing logistic systems by complementing and streamlining them. Hardware as well as software is installed according to the requirements of the individual situation.

FUNCTIONS:

- TRACEABILITY: complete traceability to the smallest packaging

- GOODS INWARD: input of delivery data and production order dates from the inventory management system into the fruitmanager database

- PRODUCTION MANAGEMENT:

• Production evaluation and analysis through registration of product quality, personnel performance and production utilisation

• All information at a glance: production status, device settings, system messages

• Automation and assistance in production of quality reports, bills of lading, rule assistant, label preview - STOCK MANAGEMENT:

• Display of crate need with storage position in real time directly on the stacker IPC

• Flexible store view at cell level (available and unavailable cells)

• Optimised display of stock and all stock movements

• Projection of all orders into the store - PACKING LINE

• Control of all devices involved in the production process (weighing machines, labelling machines, printers and palletisers)

• Display of the current order information on the packing line

• Operator management with worktime recording via industrial pc with transponder key or automatic recognition at packing line (including in relation to orders)

• Trend analyses with graphical display on the ipcs of line utilisation and productivity - WEIGHING & LABELLING

• Display of over- and underdosing of individual packages

• Recording and statistical evaluation of weights of small and transport packages as well as pallets

• Automatic control of the labeller and label machine according to production management orders - PALLETISATION

• Control of all types of palletisers manufactured

• Acceleration of order changes

• Fully automatic identification of pallets on up to three sides and heights (dispatch labels in conformity with GS1 or EPCglobal in large formats up to DINA5) - LOADING

• Automatic production of the pallet list at order position end (production)

• Automatic production of bill of lading at end of order

A solution with all the possibilities for absolute transparency, efficiency and quality.

Complete traceability throughout the entire production process according to EU178/2006

Complete stock overview of the pre-sorted products

A single ERP system; no complications with FruitManager as it is subordinate to the ERP system

Interface management of the sorting system and the connected machines in the packing line by the FruitManager

Short set-up times for job changes (approx. 30 sec.)

Quieter work on the packing lines

Savings on packing staff

Productivity analyses and evaluations

Quality reports

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

- Complete traceability throughout the entire production process

- Complete stock overview of the presorted products

- One single ERP system

- Short set-up times for order changes

- Savings on packing staff

- Quality reports

Application areas and compatibility

Downloads

Automation, controlling, monitoring and traceability

All at a glance

You always have an overview of your order management, -control and -processes as well as productivity analyses and evaluations and of the stock.

The lines with order processing, current processing status, evaluation of productivity, packages/minute, quality and much more are viewable for the production manager via the software.

The set-up time of the machines is reduced to a minimum – as they are already set automatically from the office at the beginning of the job.

Simplified management

Uncomplicated interface management between sorting system and the connected machines in the packing line is important. Everything from a single source guarantees a smooth process and optimised integration of the various scales, labellers, packing lines, etc. into the system.

Graphical visualisation

From order start to productivity analysis, you can control everything via the FruitManager software. It guarantees a better overview thanks to the clear graphical overview of the recorded data.

Your productivity will increase. The giveaway is reduced to a minimum. This means that your profit will also be increased at the end.