COMBINATION

SCALE

INTELLIGENT

MANUAL

COMBINATION

SCALE

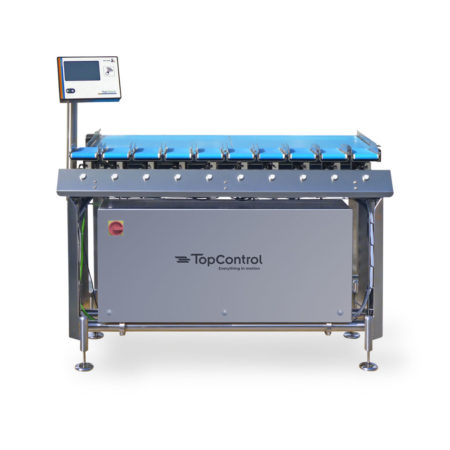

MHP 1000

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard

THE BEST SOLUTION OPTIMIZED FOR MEDIUM SIZED

vegetables, fruit, meat, fish, cheese ....

Contact us for more information

Highlights &

advantages

of the giveaway

maximisation

hygienic workstations

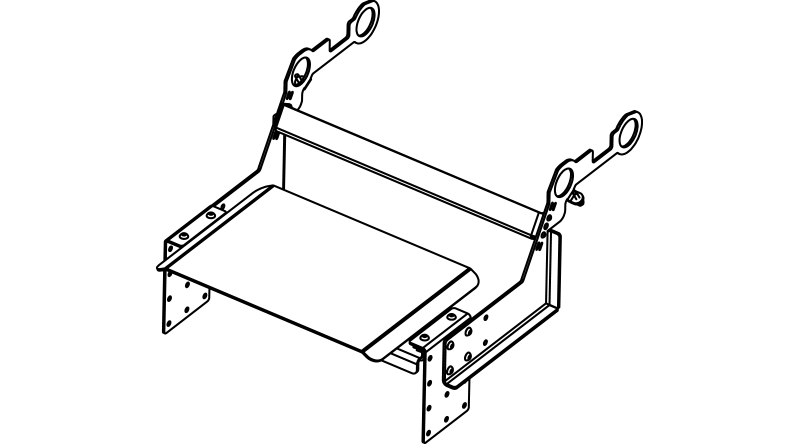

Multihead processing system MHP 1000

The multihead processing system MHP1000 determines the optimal combination of single fruits, vegetables, meat and cheese to achieve a defined target weight. The overweight of your packagings can be reduced to less than 1%. This means that you give away significantly fewer products in the packaging process.

The MHP 1000 selects the optimal combination that comes closest to the target weight. It is not possible to achieve such a precise weight by manual weighing.

The weighing trays of the MHP 1000 are loaded manually by a worker, weighed automatically and the best combination is indicated quickly and easily by the LED display. The worker puts the products into the punnet or box to be filled. This guarantees a careful weighing, which in turn increases the quality.

This saves you time and resources. Costs decrease and profits increase. The MHP 1000 is therefore a guarantee for more efficiency in your company.

In combination with the TopControl software, all weight data and staff times are recorded and flexibly evaluated.

Highlights

Maximum reduction of giveaway

Profitmaximization

ROI within 3-12 months

Robust and hygienic design in stainless steel

Minimisation of the work steps

Operable from both sides

Intuitive touch display

Efficient staff time recording with integrated RFID reader

Flexible use

Optimal integration in the TopControl software for data registration and analysis

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging – Medium vegetables/fruit |

| Application | Fruit, Vegetables |

| Fruit | Apples, Pears, Table grapes |

| Vegetables | Carrots, Eggplants, Leek, Lettuce, Peppers, Pumpkin, Radicchio, Zucchini |

- Maximum reduction of the giveaway, even with pre-filled trays.

- Profitmaximization

- Improve packaging speed with minimal personnel deployment

- ROI within 3-12 months

- Optimal integration in the TopControl software for data registration and analysis

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging – Medium vegetables/fruit |

| Application | Fruit, Vegetables |

| Fruit | Apples, Pears, Table grapes |

| Vegetables | Carrots, Eggplants, Leek, Lettuce, Peppers, Pumpkin, Radicchio, Zucchini |

Downloads

The little helper for manual weighing processes

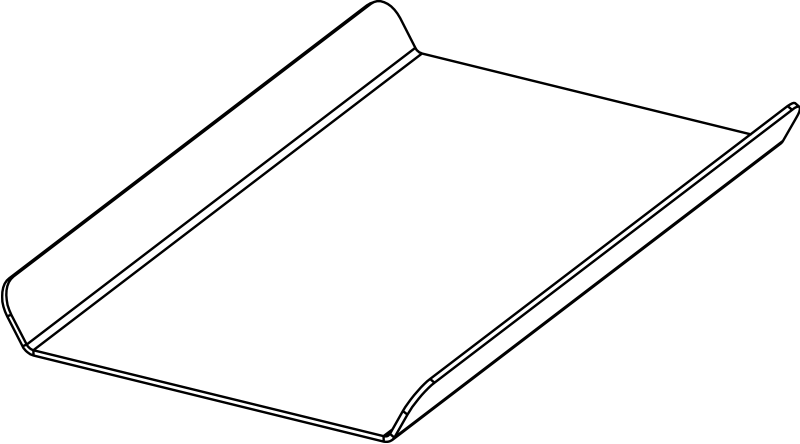

Weighing trays

The MHP 1000 is available in the options with 10 – 8 and 8 large weighing trays. The width of the weighing trays depends on the products.

For small products, the version with 10 weighing pans can be selected; the wider the products, wider weighing pans or even those with a spacing between them are required in order to achieve an optimal weighing result.

Foot extension

Ergonomic foot extensions allow adjusting the combination scale to the workers, ensuring a more comfortable work for the whole working time.

The right working height enables the workers to be faster and to tire later.

The foot extension allows an additional height of 120 mm.

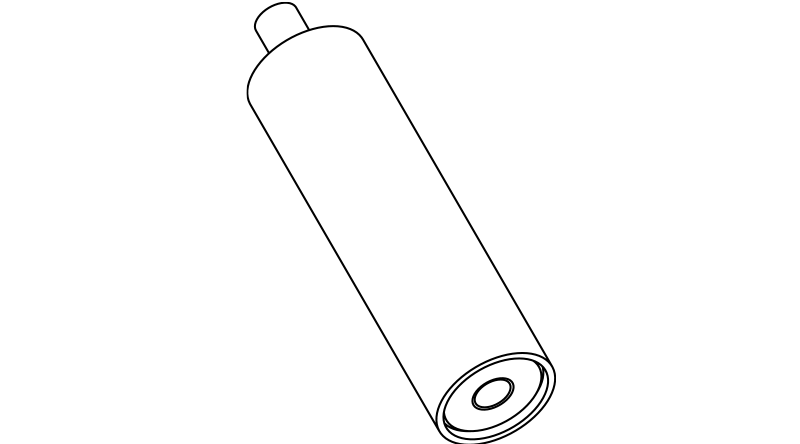

Supplementary scale

The optional supplementary scale for levelling boxes can be mounted on the MHP 1000. It is used to record the initial weight of the boxes/trays which are to be filled. After recording this initial weight, the combination scale MHP 1000 calculates the best possible weight combination between the pre-filled box and the products placed on the weighing trays. This way, the giveaway can be reduced to a minimum even below 1%.

The additional scale can be mounted on the left, right or centrally, depending on requirements.

It is supplied with a load capacity/division of 15 kg/5 g and 30 kg/10 g.

The additional scale has a size of 300×400 mm.

Upgrade your machines with our software solutions

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.