COMBINATION

SCALE

COMBINATION

SCALE

MHP2000

COMBINATION

SCALE

MHP 2000

THE BEST SOLUTION OPTIMIZED FOR MEDIUM SIZED

vegetables, fruit, meet, fish & cheese: zucchini, apples, pears, mango, aubergines, karotts, paprika, leek, radicchio, mushrooms....

Contact us for more information

Highlights &

advantages

of the giveaway

packaging speed

small packaging

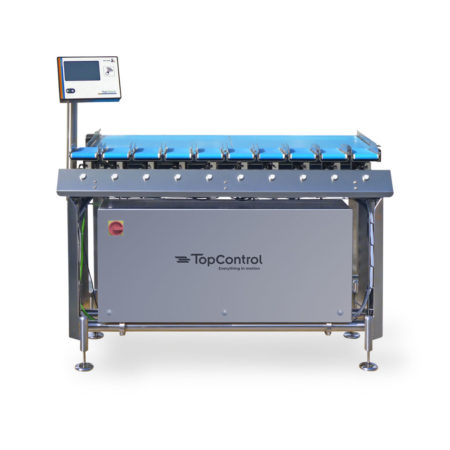

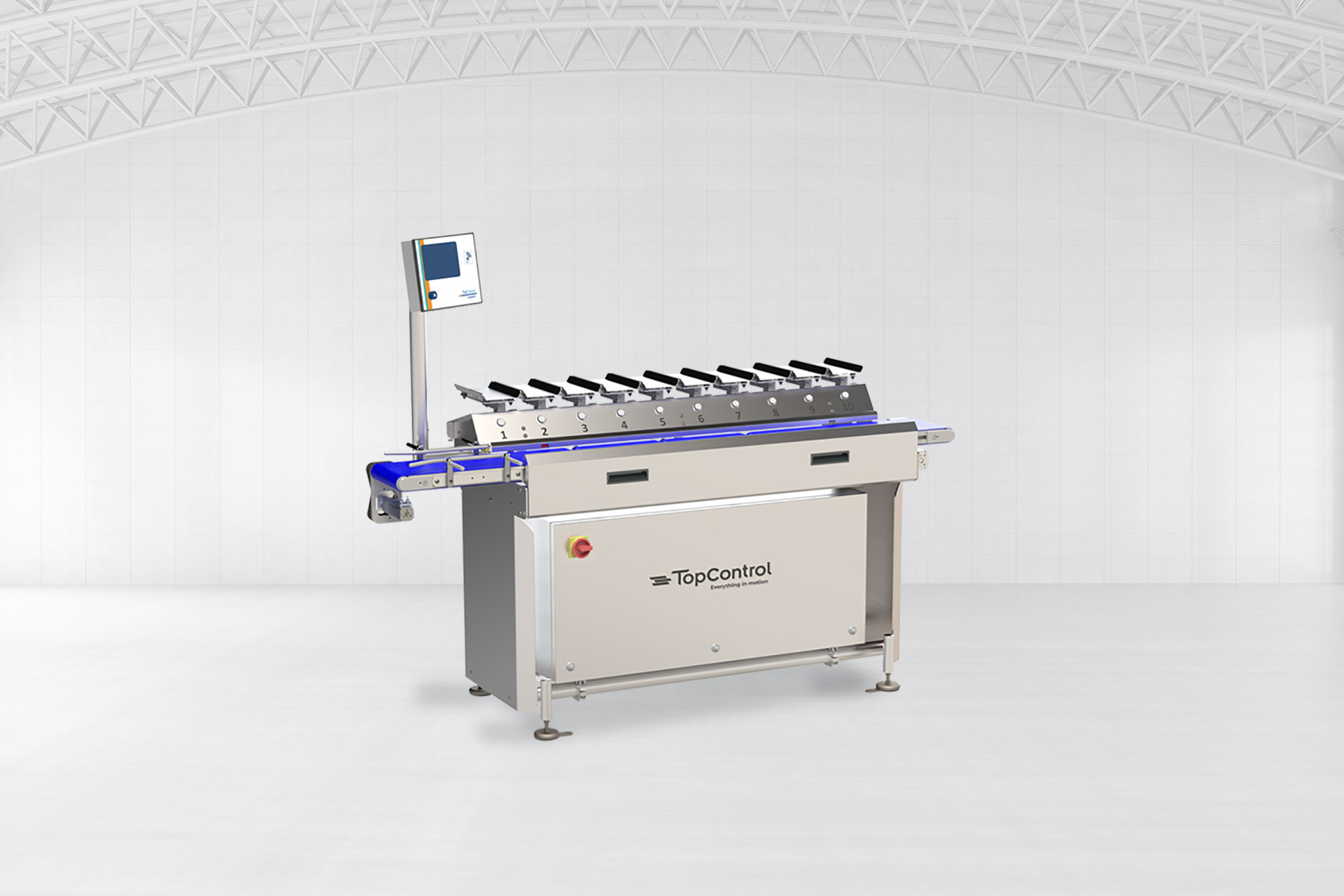

Multihead processing system – MHP 2000

With the MHP 2000 combination scale, manually pre-filled small packages of fruit, vegetables, meat, fish and cheese can be filled with minimal giveaway.

With the MHP 2000, pre-filled or empty packs of fruit, vegetables, meat and cheese can be filled to the desired target weight with minimal giveaway. Thanks to a scale built into the infeed belt, the MHP 2000 can calculate in real time the product or combination of products missing to the target weight. The worker only needs to observe the green LED indicators to reach the target weight. The MHP2000 is a flexible weighing system that, in addition to a standard weighing mode for a completed product also has options for weighing on a conveyor belt, combination weighing and throughput.

The MHP2000 offers a significant increase in efficiency in the packaging process. The ten weighing scales on the MHP2000 are manually loaded by an operator to add the final piece to the prefilled small punnets for automatic weight optimization. With two scales installed into the infeed belt, the MHP2000 can determine the missing product amount or the missing product combination totals in real time. The operator only needs to observe the green LED-indicator to reach the defined target weight. Thus, both time and resources can be saved with the MHP 2000.

This noticeably reduces costs and increases profits. Connected with the TopControl software all weights and staff times are completely recorded, for efficient evaluation and reporting.

More profit, fewer work steps

Packing speed: also > than 25 packs/minute

Maximum reduction of giveaway

Packing according to WELMEC 6.4/e for pre-packed goods

Profitmaximization

ROI within 3-12 months

Suitable for small packaging

Efficient working time recording through integrated transponder reader

Minimisation of the work steps

Robust and hygienic construction in stainless steel

Optimal integration in the TopControl software for data registration and analysis

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging – small & medium/large products |

| Application | Cheese, Fruit, Meat, Vegetables |

| Fruit | Pears, Table grapes |

| Vegetables | Carrots, Eggplants, Ginger, Leek, Mushrooms, Onion, Patatoes, Peppers, Pumpkin, Radicchio, Soup vegetables, Tomatoes, Zucchini |

| Meat | Meat, Sausage |

| Cheese | Cheese |

- Maximum packaging speed and minimisation of work steps

- Profitmaximization

- Suitable for small punnets of fruit, vegetables, cheese and meat.

- Maximum reduction of giveaway

- ROI within 3-12 months

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging – small & medium/large products |

| Application | Cheese, Fruit, Meat, Vegetables |

| Fruit | Pears, Table grapes |

| Vegetables | Carrots, Eggplants, Ginger, Leek, Mushrooms, Onion, Patatoes, Peppers, Pumpkin, Radicchio, Soup vegetables, Tomatoes, Zucchini |

| Meat | Meat, Sausage |

| Cheese | Cheese |

Downloads

Even more efficiency in the weighing process

Display

The workers log in via the intuitive display. The exact time and weight data are recorded specifically for each order and then analysed in the appropriate software. This also guarantees the traceability of the packs with detailed data.

Ergonomics

TopControl’s weighing and labelling solutions are made of robust and hygienic stainless steel and comply with the standards for the food industry. Ergonomically designed for a high level of operating comfort, they can be adapted to the workers so that working on them is easier and more comfortable.

Ergonomic foot extensions allow the combination scale to be adapted to the workers and thus ensure more comfortable working for the entire working time.

The right working height enables the workers to be faster and to tire later.

Weighing trays

The 10 weighing trays of the MHP 2000 are available with dimensions 250 x 105 mm (L x W). These are used to calculate the optimum weight with the minimum giveaway.

Upgrade your machines with our software solutions

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.