COMBINATION

SCALE

COMBINATION

SCALE

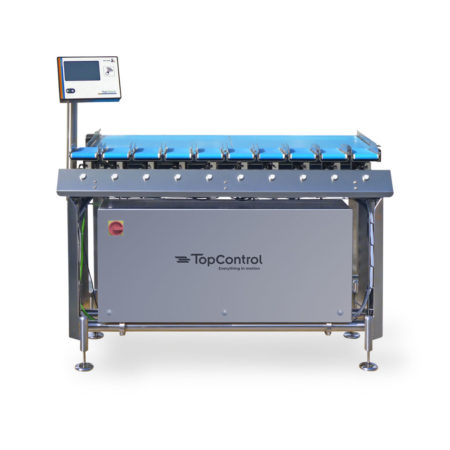

MHP1300

COMBINATION

SCALE

MHP 1300

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard

THE BEST SOLUTION OPTIMIZED FOR MEDIUM SIZED

vegetables, fruit: zucchini, aubergines, karotts, onion, paprika, leek, radicchio ....

Contact us for more information

Highlights &

advantages

of the giveaway

maximization

construction

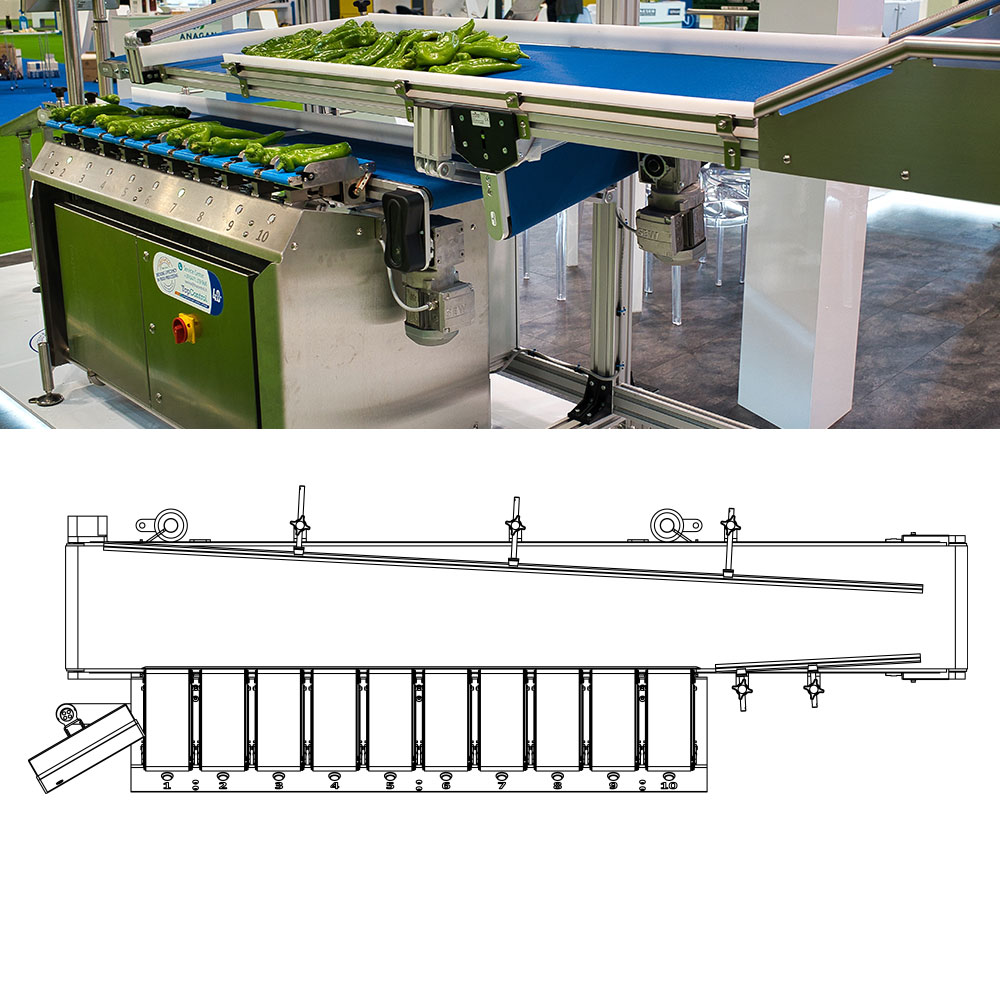

Multihead processing system MHP 1300

With the combination scale MHP 1300, empty small packages of medium-sized products can be filled manually with a minimal giveaway.

With the MHP 1300 you can determine the optimal combination of unpacked fruit, vegetables, cheese, meat or fish to reach the defined target weight and thus reduce the giveaway. The weighed quantities are then automatically transferred to the next station. The accuracy of the scales and the optimised weight of the goods improve packaging speed and reduce staff management. This noticeably reduces costs and increases profits.

In combination with the TopControl software, all weight data and working times are recorded and flexibly evaluated.

Increasing productivity through process optimisation

Reduction of the giveaway to less than 1%

Profitmaximization

ROI within 3-12 months

Minimisation of the work steps

Flexible use

Transportbeltforautomaticormanualtransferofthecombinedproduct to the following station

Robust and hygienic design in stainless steel

Intuitive touch display

Efficient staff time recording with integrated RFID reader

Optimal integration in the TopControl software for data registration and analysis

Downloads

Application areas and compatibility

| Software | FoodProcess, StatisticsWeights |

|---|---|

| Packaging | Small packaging – Medium vegetables/fruit |

| Application | Vegetables |

| Vegetables | Carrots, Eggplants, Leek, Lettuce, Onion, Peppers, Radicchio, Soup vegetables, Zucchini |

- Reduction of the giveaway to less than 1%

- Conveyor belt to the following station

- Profitmaximization

- Improve packaging speed with minimal personnel deployment

- ROI within 3-12 months

- Optimal integration in the TopControl software for data registration and analysis

Application areas and compatibility

| Software | FoodProcess, StatisticsWeights |

|---|---|

| Packaging | Small packaging – Medium vegetables/fruit |

| Application | Vegetables |

| Vegetables | Carrots, Eggplants, Leek, Lettuce, Onion, Peppers, Radicchio, Soup vegetables, Zucchini |

Downloads

Transportbeltforautomaticormanualtransferofthecombinedproduct to the following station

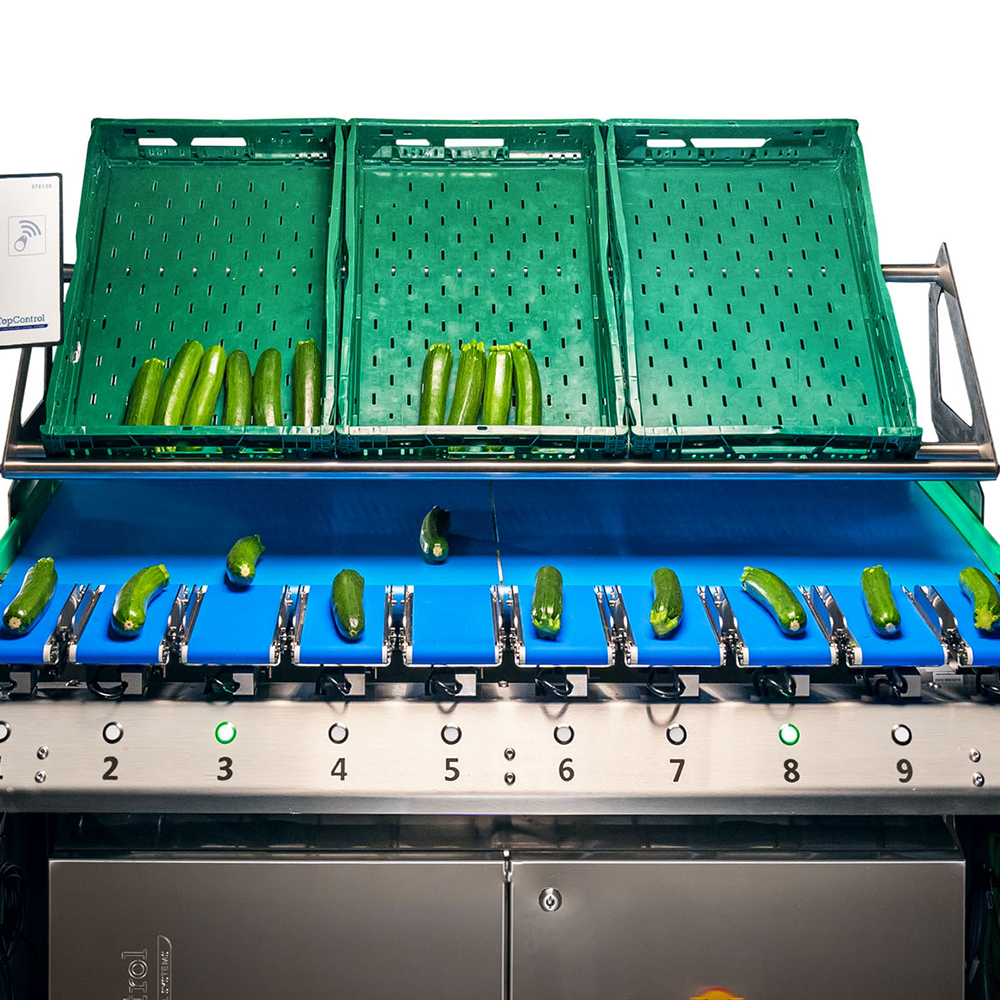

Weighing belts

The 10 weighing belts of the combination scale MHP 1300 are available with the dimensions 250 x 105 mm (L x W). They calculate the optimum weight with the minimal giveaway & output it.

Storage for boxes

To ensure fast and optimised work, optional, ergonomically adapted box storage can be mounted on the combination scale. The input products can be placed on this. This enables a comfortable way of working that has been thought through as a whole.

The workers always have the full boxes at hand.

Infeed belt

The incoming products reach the combination weigher via the infeed belt. From there, the worker manually places them on the weighing trays so that the optimal combination can be calculated.

The infeed belt is mounted in an ergonomically sophisticated way to avoid wide grips and uncomfortable postures.

Upgrade your machines with our software solutions

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.