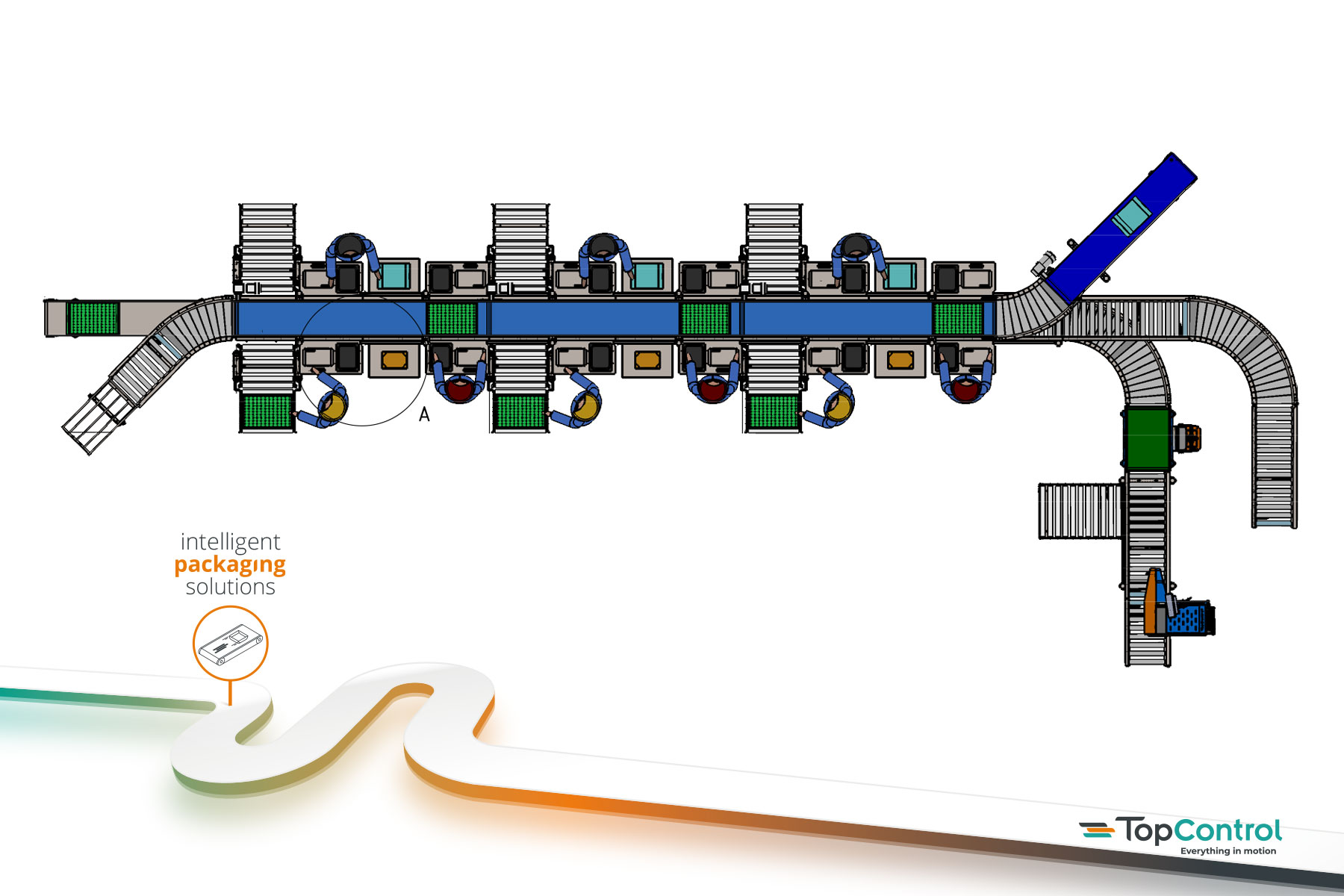

What were the benefits of installing our products?

-

The standard output was previously 0.4 boxes / person / minute. With the use of our machines, the output could be raised to a maximum of 3 crates / person / minute.

-

It took 70 per cent less staff to produce the same amount.

-

The “Statistic Weights” software used records the entire processes and provides a better overview of the process chain. In addition, the web API can be used to better control and automate the inventory management system. With the live export, article maintenance is simplified and performance data is analysed more quickly for further processes. Working hours were also recorded accurately and could contribute to optimising staff management. The increased transparency is partly responsible for the above improvements.

THAT MEANS CONCRETELY

More control of the performance / person, analyses and working time recording as well as the resulting increase in profit are just some of the advantages of using our products.

More control of the performance / person, analyses and working time recording as well as the resulting increase in profit are just some of the advantages of using our products.