PRICE

LABELLER

PRICE

LABELLER

SPT 500

WEIGHINGTABLE

&

PRICELABELLER

SPT 500

Best solution for weighing and labelling for:

MEAT · FISH · CHEESE

Contact us for more information

Highlights &

advantages

weighing & labelling

and hygienic

weighing platform

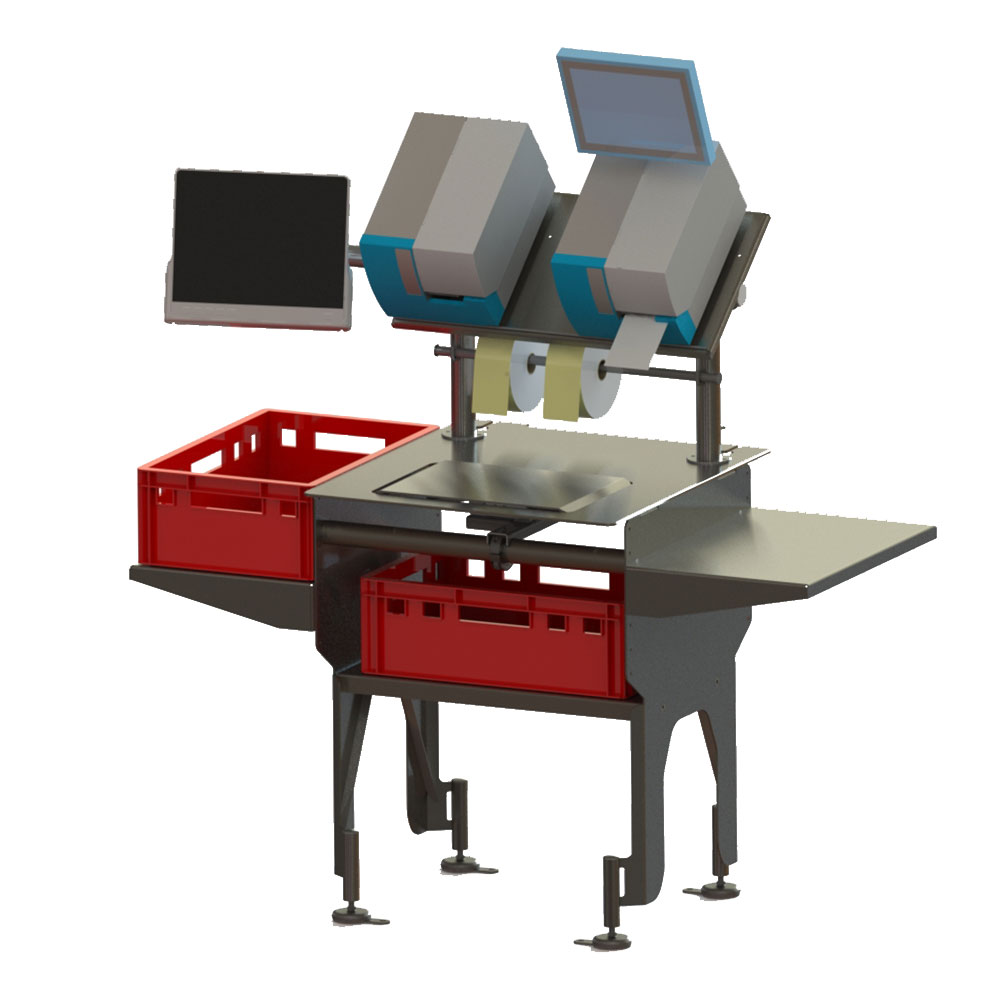

Price Labeller SPT 500

The ergonomic SPT 500 price labeller is an intelligently designed weighing and labelling table. It simplifies different harvesting, production or packaging processes, especially for the meat, fish and cheese industries. Its modular design allows it to be used in a wide variety of scenarios: Weight registration, price labelling and labelling. The SPT 500 is constructed of stainless steel and specifically designed with the often limited space in the production area in mind. The table creates optimal working conditions in any production environment.

Its great advantage is that the table can be equipped with the following components: Box storage for incoming and outgoing products, integrated weighing platform, up to 2 display holders for industrial PCs or TopControl displays, time recording via RFID reader, two labellers and/or price labellers and decorative label holder. All these components are ergonomically designed to help your workers work productively and quickly, because they have everything they need at hand.

Weighing and price labelling in one innovative solution

Profitmaximization

ROI 3-12 month

Suitable for transport and small packaging

Compact design

Ergonomically designed price labeller: with scale + labeller

Recording the weight data of all packages

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager, StatisticsWeights |

|---|---|

| Packaging | Price labeller, Small packaging, Small packaging – small & medium/large products, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Meat | Cold cuts, Meat, Poultry, Sausage |

| Cheese | Cheese |

- Integrated weighing platform in the table

- Individually adaptable (height, width, extensions)

- Profitmaximization

- Robust, ergonomic and hygienic design in stainless steel

- Various applications:

- Weighing and recording

- Weighing and labelling

- Harvest recording

Application areas and compatibility

| Software | FoodProcess, Fruitmanager, StatisticsWeights |

|---|---|

| Packaging | Price labeller, Small packaging, Small packaging – small & medium/large products, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Meat | Cold cuts, Meat, Poultry, Sausage |

| Cheese | Cheese |

Downloads

All-in-one solution to increase productivity and quality

Customised

Its great advantage is that the table can be equipped with a wide variety of components for a well thought-out process flow:

- Box storage for incoming and outgoing products

- Different weighing platforms

- Up to 2 display holders for industrial PCs

- Working time recording via RFID reader

- Up to two labellers and/or price labellers

- Decorative label holder

No matter how you would like to have the SPT 500, with the extensions and different assembly types, it is no problem at all.

Ergonomics

TopControl’s weighing and labelling solutions are made of robust and hygienic stainless steel and comply with the standards for the food industry. Ergonomically designed for a high level of operating comfort, they can be adapted to the working process so that working on them is easier and faster.

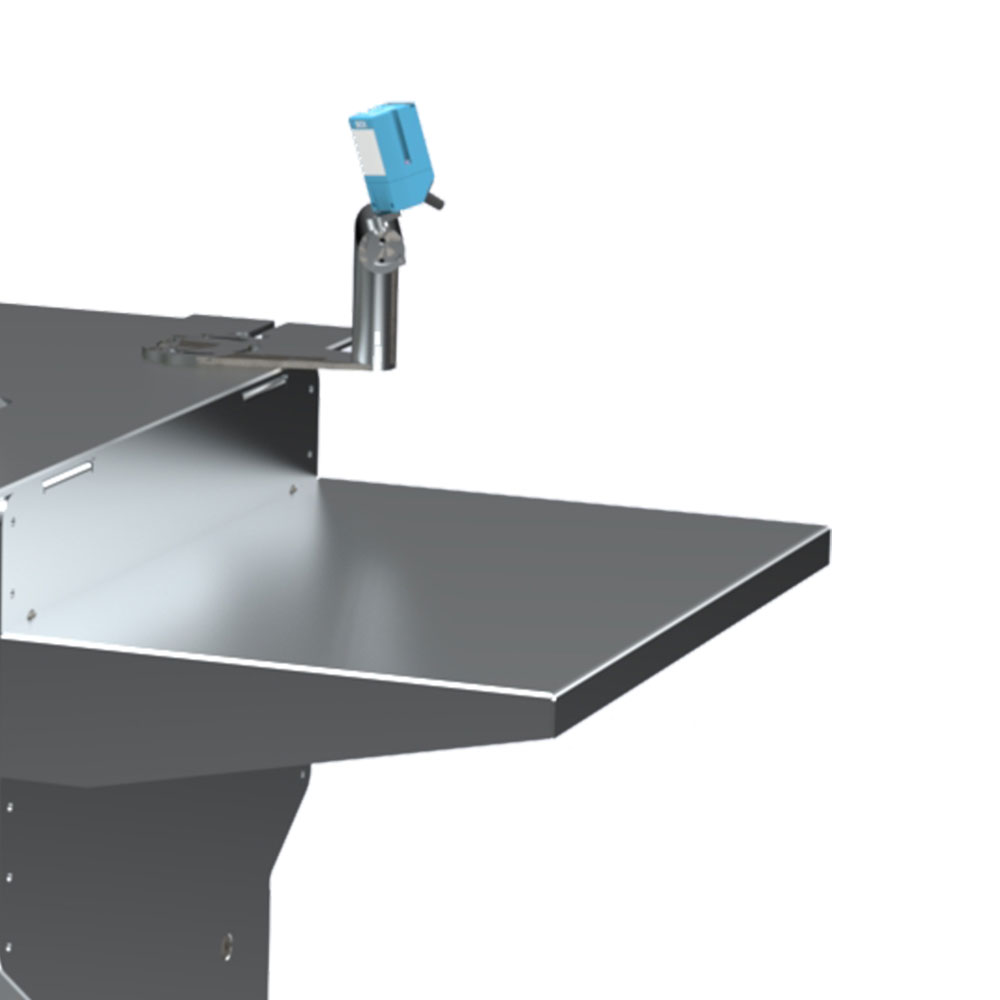

Integrated weighing platform

The integrated weighing platform records the weights of the packaged goods and prints the matching labels at the same time. Integrated in the network, the weights are recorded directly in the central TopControl software. The high accuracy of the scale and the intuitive operation allow considerable savings in time and product costs.

Our software solutions for 360° smart processes

All our machines are compatible with our software solutions, making them even smarter. The labeller can be connected to the FruitManager so that you have a precise overview of all processes. You can control them fully automatically and track the production steps. With the TopControl FruitManager solution, your company saves time and money while increasing efficiency and quality in the production process.